SPRAGUE S-216-J PUMP FAQ

What It Does

The Sprague S-216-J is a positive-displacement hydraulic pump driven by compressed air. It uses relatively low air pressure, acting on a large area piston, to produce high liquid pressure using a small-area output piston. Pumped media can include water, oil and most corrosive chemicals. These pumps are rugged, industry-proven, low maintenance and are non-arcing and non-sparking which makes them a good option in hazardous or confined areas.

How It Works

When air pressure is applied to the Sprague pump, it reciprocates rapidly as it initially pumps liquid. As the liquid pressure increases and nears the desired level,

it slows to a stop due to the liquid pressure balancing the air pressure. This liquid-air pressure balance is maintained indefinitely in a holding condition with minimal energy consumption and without increase in fluid temperature or parts movement. (A motor-driven pump in a holding condition must continue running to maintain a pressure level. Excess liquid must be bypassed or recirculated back to the reservoir, resulting in energy-loss, heat build-up, and the need for bypass components and a larger reservoir.)

Uses

The Sprague air-driven pumps can produce pressures in excess of 30,000 psi and are often used for hydrostatic testing of hoses, pipes, valves, fittings and

other hydraulic vessels and products. They are also commonly used to deliver high pressure liquids required by production machinery for holding, clamping, forming, shearing and punching. A typical application is a hydraulic press where long holding cycles are necessary or where a short stroke and high force are required. High and low volume Sprague S-216-J pumps can be combined to produce an economical combination of both moderate flow and high pressure. Because Sprague air-driven pumps are compact, they can be installed directly on individual machines or test equipment as the direct power source.

Pump Options

S-216-J pumps can be ordered in different versions for varied applications: double-acting for high flow, separated pumps for non-contamination, non-lubricated for use with oil-free air, pumps with built-in reservoirs and pumps for use with de-ionized water. The pumps can also be special ordered with Viton, EPR, Neoprene or other sealing material to accommodate most liquid chemical applications.

Frequently Asked Questions

Q. What kind of liquids can I run through these pumps?

A. The liquid portion of the pump is made of stainless steel and the pump seals are available in multiple options which means that most liquids can be readily accommodated. See wetted materials question below.

Q. When is the Severe Service pump recommended?

A. Sprague recommends using the JB or JBN pump when pumping water or other low lubricity fluids. The "B" improvement incorporates a new bushing design that reduces alignment issues in the liquid section and provides longer seal life. This particularly improves seal and piston life when pumping water or other low lubricity fluids (up to 5X longer). NOTE: This is strictly an internal improvement and does NOT affect external dimensions NOR does it affect pumping specifications of the unit (other than longevity). The "JB" and "JBN" version pumps are direct replacements for the "J" and "JN" versions.

The Severe Service "B" versions are also highly recommended in any high cycle application as they have a longer pump life. (Also see below: "Why can I no longer buy the higher ratios pumps in the old "J" Series?")

Q. How compact are these pumps?

A. The standard S-216-J pump is 8 1/2" in diameter and 9 3/4" tall and weighs about 14 lbs. Other versions of the pump may be different in size. You can see drawings and other specifications for the pumps on the data/spec sheet.

Q. How much control do I have over liquid output pressure?

A. The output pressure is basically infinitely variable within the pressure range of that pump. Increasing the air pressure will increase the liquid output pressure a proportional amount. For instance, varying the air pressure on 10:1 pump anywhere from 10 psi to 100 psi will give you a resulting liquid outlet pressure of anywhere from 100 psi to 1000 psi.

Q. I can control the liquid outlet pressure by adjusting the air pressure but can I control the liquid flow rate too?

A. Yes, you can. You accomplish this by restricting the liquid flow or by changing the air flow rate (this will adjust the pump cycle rate.)

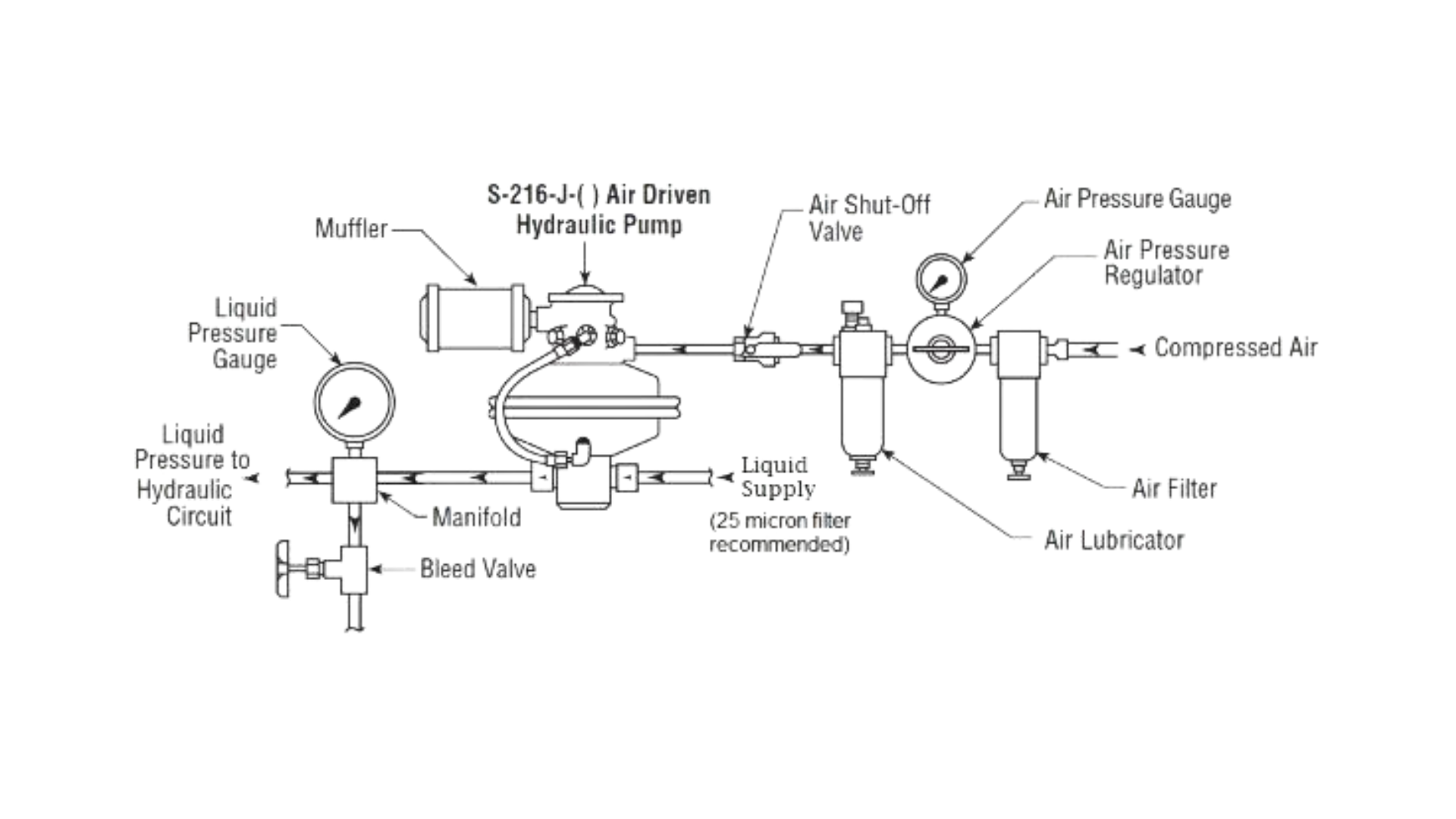

Q. Do I need to lubricate the compressed air that I use to run this pump? (Two answers.)

A1. Yes you do. If you buy the standard pump you will need to use an automatic air lubricator in the air supply before the pump. (A standard pump will NOT have an "N" immediately before the ratio number as seen in this example: S-216-J-100.) Typically a common FRL (Filter/Regulator/Lubricator) is used for this purpose. Sprague recommends a good quality SAE #10 air tool oil which is readily available from industrial supply houses like McMaster-Carr and Grainger, or locally from auto parts stores or Walmart (Example brands: Lucas, Marvel, Ingersoll, Amflo, Bostitch, Mobil, Interstate Pneumatics and other.)

A2. And no. If you purchase a version with an "N" in the model designation right in front of the ratio number ("N" for non-lubricated air supply), then you will not need to lubricate the incoming air. As an example: S-216-JN-100 would be a pump with a 100:1 pressure ratio that is suitable for use with a non-lubricated air supply.

Q. How much air will this pump use?

A. It depends on the air pressure required and on the pump flow rate. At any time that the pump is holding maximum liquid pressure with no flow, then there is no air usage. Air flow is greatest when liquid pressure is low and the pump is allowed to cycle rapidly. Nominal pump performance on the spec sheets is based on 50 or 80 SCFM at 100 psi (as noted on each chart).

Q. How low an air pressure will these pumps run at?

A. As low as 15 psi (25 psi for non-lubricated JN pumps).

Q. Do the higher pressure pumps use more air?

A. No, not necessarily. The pumps have the same air module. Higher pressure pumps use the same amount of air but have lower liquid flow rates. Lower pressure pumps have correspondingly higher liquid flow rates.

Q. Does this pump require positive liquid pressure on the inlet side of the pump (flooded suction)?

A. Some do and some do not. Contact us if your application does not have positive pressure at the inlet. In general, the higher pressure pumps require more care in ensuring adequate liquid inlet pressure.

Q. What materials are used for the wetted section of the pump?

A. The standard pump uses the materials below (other seal options available for most applications):

Liquid Body: 303 Stainless Steel

Liquid (driven) Piston: 416 Stainless Steel Chrome Plated

Piston O-Ring: Nitrile

Piston Back-up Ring: Teflon (or equivalent compound)

Check Valve Body: 416 Stainless Steel

Check Valve Poppet: 17-4ph Stainless Steel

Check Valve Spring: 302 Stainless Steel

Check Valve Seal: Nitrile

The common alternate seal & o-ring materials are: Neoprene, Viton and EPR (other possibilities on request).

Q. Do these pumps require mufflers?

A. In most applications it is advisable to run a muffler on the air exhaust. Air exhausts rapidly and can be noisy if not muffled.

Q. Why can I no longer buy the higher ratios pumps in the old "J" Series?

A. Sprague elected in 2014 to upgrade the high pressure ratio J-series pumps (125:1 - 300:1) to the new "JB" version. This means that they discontinued the high ratio J-series and JN-series and replacing them with the JB and JBN. Repair kits and parts are still available for these older "J" version pumps.

The "B" improvement incorporates a new bushing design that reduces alignment issues in the liquid section and provides longer seal life. This particularly improves seal and piston life when pumping water or other low lubricity fluids (up to 5X longer). NOTE: This is strictly an internal improvement and does NOT affect external dimensions NOR does it affect pumping specifications of the unit (other than longevity). The "B" version pumps are direct replacements for the "J" versions.

The lower pressure pumps (10:1 - 100:1) will continue to be available in the J and JN version but you may elect to buy the improved version in any ratio 35:1 or greater. The "B" version is always highly recommended when pumping water or any other low lubricity fluid, and it is recommended for applications with high cycle rates.

A 101:1 ratio pump was also added so that there would be a true 10,000 PSI maximum pressure pump available with NPT liquid outlet porting.

Q. What company makes these pumps?

A. Sprague pumps were initially designed and build by Bob Sprague starting in 1946. Sprague Engineering was bought by Teledyne in 1966, and became Teledyne Sprague. In 1992 it moved to Ohio and became part of the Teledyne Republic company before moving again in 1995 to Brecksville, Ohio under the Teledyne Fluid Systems name.

More recently, In 1999, the company was acquired by Curtiss-Wright and it was then sold in 2017 to High Pressure Equipment Company (HiP). a division of Graco. HiP specializes in making fittings, valves, tubing and accessories for the high pressure and very high pressure markets (up to 150,000 psi). Their products also include reactors, pressure vessels, pumping systems and intensifiers.