HiP eTensifier Pump Info & FAQ

What It Does

The eTensifier high pressure hydraulic pump simply plugs into a wall outlet... it does not require an air compressor. This pump represents new technology

introduced by three industry leaders…patent protected motors and controls from Graco, proven hydraulic pumps from Sprague and high pressure components and customer service from HiP. The eTensifier will deliver pressures to 36,500 psi with a quiet electric motor, a

smoother flow rate from zero to full pressure and controls that include an industry-first pressure test mode that allows you to set a defined pressure and walk away. This is plug'n play pumping. The motor and controls are covered by a two year warranty.

Special Features

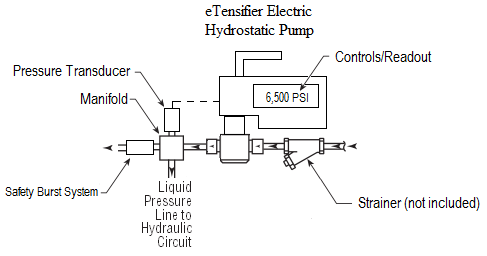

Because the pump is equipped with a transducer, it is able to monitor system pressure and turn off the motor when set pressure is reached. The pump automatically restarts when needed to maintain the pre-selected pressure in the system. It will continue to cycle on and off as needed, similar to how an air hydrostatic pump works. This saves energy and reduces the unwanted heat build up caused by other continuously running hydraulic systems that have to "dump" excess pressure through a relief valve. The transducer also allows on-board pressure display on the control screen eliminating the need for an additional pressure gauge.

In addition, the eTensifier features a new quick-connect system for exchanging the pump high-pressure section to facilitate routine maintenance without taking the whole pump out of commission. The pump head can be changed in minutes.

Uses

The HiP eTensifier pumps can produce pressures in excess of 35,000 psi and are ideal

for hydrostatic testing of hoses, pipes, valves, fittings and other hydraulic vessels and

products. They can also be used to deliver high pressure liquids required by production

machinery for holding, clamping, forming, shearing and punching. A typical application is a hydraulic press where long holding cycles are necessary or where a short stroke and high force are required.

Pump Options

These pumps can be special ordered with Viton or EPR sealing material to accommodate most liquid chemical applications. Available in 115 VAC and 240 VAC.

Frequently Asked Questions

Q. How much control do I have over liquid output pressure?

A. The output pressure is basically infinitely variable within the pressure range of that pump. A knob on the control box of the pump allows you to select the pressure you want the pump to maintain.

Q. Are you saying that I can enter an specific desired pressure on the screen, hit the button and walk away and it will automatically pump up to and hold that pressure?

A. Correct, that is exactly what this pump will do. Think of it as a "smart pump." And it will do it repeatedly and consistently.

Q. Can I control the liquid flow rate too?

A. You can, to a certain extent. You accomplish this by selecting one of five different "gain" settings to determine pump speed. The pump is programmed to pump at high speed until it reaches 50% of set pressure then is slows to approach the final pressure more accurately. You can select 5 different gain settings which will determine whether you pump at the highest flow rate (5), the most accurate rate (or least likely to overshoot the desired pressure) (1) or something in between.

Q. What kind of liquids can I run through these pumps?

A. The liquid portion of the pump is made of stainless steel and the pump seals are available in multiple options which means that most liquids can be readily accommodated. See wetted materials question below.

Q. How compact are these pumps?

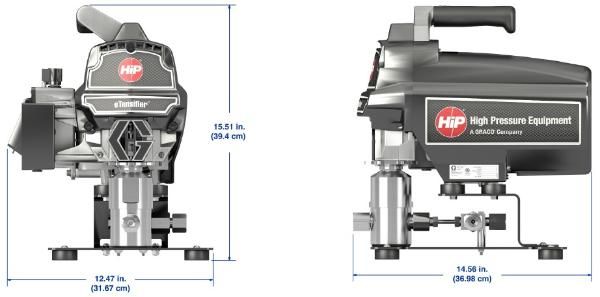

A. The standard eTensifier pump is 15 in. long x 15 in. tall x 12 in. wide and weighs about 46 lbs. You can see drawings and other specifications for the pumps on the data/spec sheet.

Q. Why is the published flow rate on these pumps lower than on the J-Series air version?

A. They are rated differently. The J-Series Sprague pumps have been historically rated at their maximum flow rate (with essentially no back pressure on the pump). The eTensifier pumps have been rated instead using the more traditional flow-at-rated-pressure value, which is lower. The air pumps also pump much less fluid when they approach their stall (high) pressure.

Q. Do I need to lubricate this pump?

A. No, you do not. This pump does have a cycle counter so that you can keep track of pump life for maintenance purposes.

Q. How much electrical power will this pump use?

A. It plugs into a standard 115 VAC or 240 VAC wall outlet (115 VAC,15A, 50/60 Hz or 240 VAC, 9A, 50/60 Hz).

Q. Does this pump require positive liquid pressure on the inlet side of the pump (flooded suction)?

A. Some do and some do not. Contact us if your application does not have positive pressure at the inlet. In general, the higher pressure pumps require more care in ensuring adequate liquid inlet pressure.

Q. What materials are used for the wetted section of the pump?

A. The standard pump uses the materials below (other seal options available for most applications):

Liquid Body: 303 Stainless Steel

Liquid (driven) Piston: 416 Stainless Steel Chrome Plated

Piston O-Ring: Nitrile

Piston Back-up Ring: Teflon (or equivalent compound)

Check Valve Body: 416 Stainless Steel

Check Valve Poppet: 17-4ph Stainless Steel

Check Valve Spring: 302 Stainless Steel

Check Valve Seal: Nitrile

The common alternate seal & o-ring materials are: Viton and EPR.

Q. Is this pump noisy?

A. No. The electric eTensifer actually runs more quietly than its S-216-J Series (air) counterpart.

Q. How similar is the pump head on the eTensifer to the old "J" Series pumps we are familiar with?

A. It's the same. The internal portion of the pump head, and the check valves, are identical to the Sprague JB-series pumps.

Q. What company makes the eTensifer pumps?

A. The Sprague Products line of pumps was sold in 2017 to High Pressure Equipment Company (HiP), a division of Graco. HiP specializes in making fittings, valves, tubing and accessories for the high pressure and very high pressure markets (up to 150,000 psi). HiP produces the eTensifier pumps which are a combination of the well known Graco paint sprayer technology and the Sprague high pressure hydrostatic pump heads.

Q. Does the motor keep running after the pump reaches the set pressure like other electric powered hydraulic pumps?

A. No. The pressure transducer, in the schematic above, senses the pressure and turns off the motor until it is needed again. The motor will then turn back on, re-establish the set pressure (sometimes in just one pump cycle) and turn right back off again. This saves power, reduces both heat build up and wear and tear and it also eliminates the need for a pressure relief valve circuit that must recirculate fluid back to the reservoir side of the system.